The MiniRex Project - The Subframes & Chassis

2/8/20

This weekend I worked out that the MX5 subframe wasn’t going to fit where I want it too due to the location of the turbo. They just got in the way of each other. Not by much but enough to annoy me.

After lots of procrastinating and an announcement from the VIC government that stage 4 restrictions for COVID were going to kick in tonight, I bit the bullet and decided it’s best to make my own subframe rather than mix the WRX & MX5 ones together.

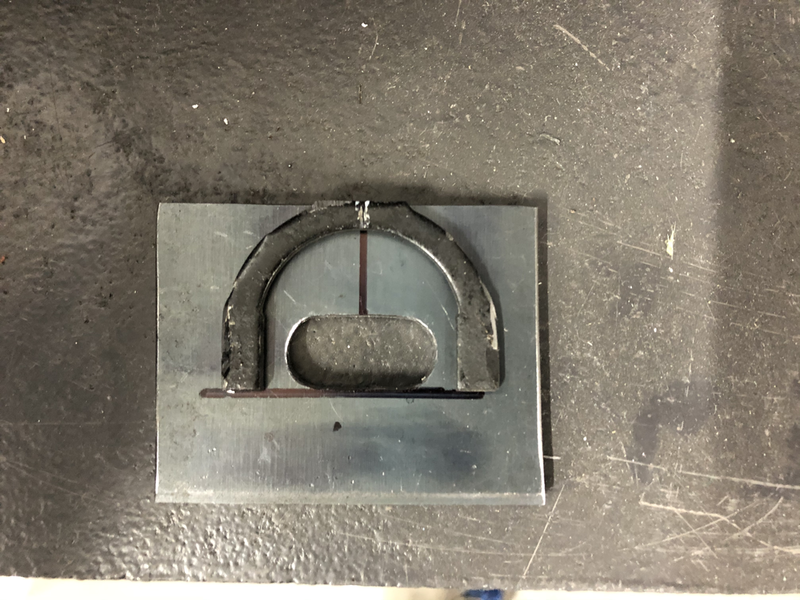

Out came the grinder and the welder and away I went. First I had to cut the WRX subframe in half as I plan to still use it. (At this stage anyway). Then I mounted some 50x25 RHS to the engine subframe as a base for control arms and hubs to mount too. Then I had to make the lower control arm mounting plates with the camber adjustment ready to weld to the base frame. I removed the adjusting brackets from the MX5 subframe and reused them. Much easier than making the, from scratch.

A time consuming job but will be better in the long run. Should look cleaner too.

This weekend I worked out that the MX5 subframe wasn’t going to fit where I want it too due to the location of the turbo. They just got in the way of each other. Not by much but enough to annoy me.

After lots of procrastinating and an announcement from the VIC government that stage 4 restrictions for COVID were going to kick in tonight, I bit the bullet and decided it’s best to make my own subframe rather than mix the WRX & MX5 ones together.

Out came the grinder and the welder and away I went. First I had to cut the WRX subframe in half as I plan to still use it. (At this stage anyway). Then I mounted some 50x25 RHS to the engine subframe as a base for control arms and hubs to mount too. Then I had to make the lower control arm mounting plates with the camber adjustment ready to weld to the base frame. I removed the adjusting brackets from the MX5 subframe and reused them. Much easier than making the, from scratch.

A time consuming job but will be better in the long run. Should look cleaner too.

7/8/20

I’m glad I have a hoist. It makes life so much easier doing these builds.

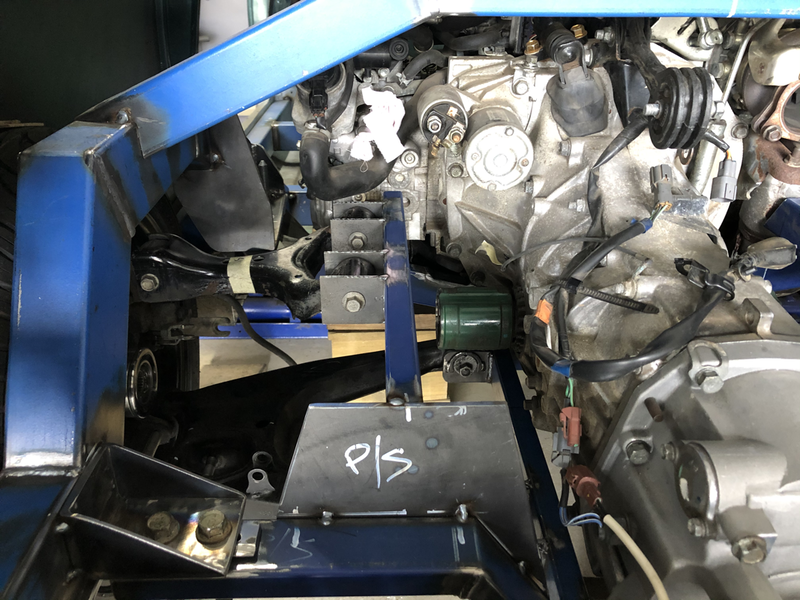

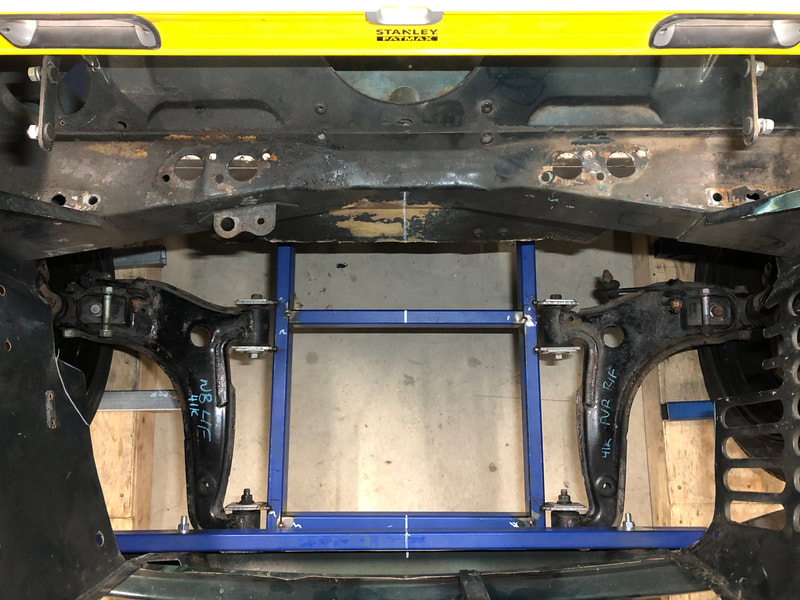

Tonight was a win in my opinion. While I didn’t do much, I managed to tack the subframe I made to the engine subframe to make it all one piece. It took a while to get it mm perfect but in the end was worth it.

Finished with the exact track width I wanted and it sits perfectly centre of the engine and the body as well. The wheels sit exactly where I wanted them too in regards to the wheel arch location. I even have a bit of wiggle room in case I have to move the engine and drive chain forward a cm or two which is handy.

I just need to sort out the height and continue on with making a mounting point for the upper control arms.

I’m glad I have a hoist. It makes life so much easier doing these builds.

Tonight was a win in my opinion. While I didn’t do much, I managed to tack the subframe I made to the engine subframe to make it all one piece. It took a while to get it mm perfect but in the end was worth it.

Finished with the exact track width I wanted and it sits perfectly centre of the engine and the body as well. The wheels sit exactly where I wanted them too in regards to the wheel arch location. I even have a bit of wiggle room in case I have to move the engine and drive chain forward a cm or two which is handy.

I just need to sort out the height and continue on with making a mounting point for the upper control arms.

30/8/20

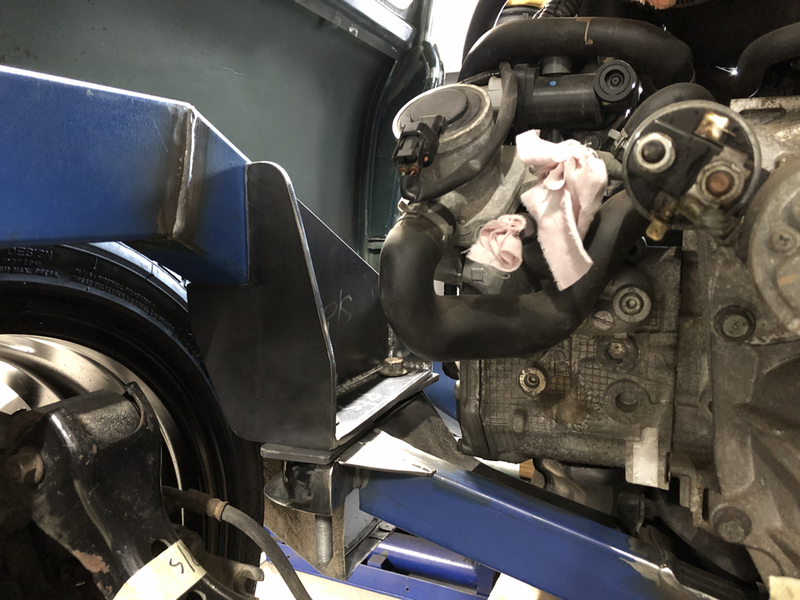

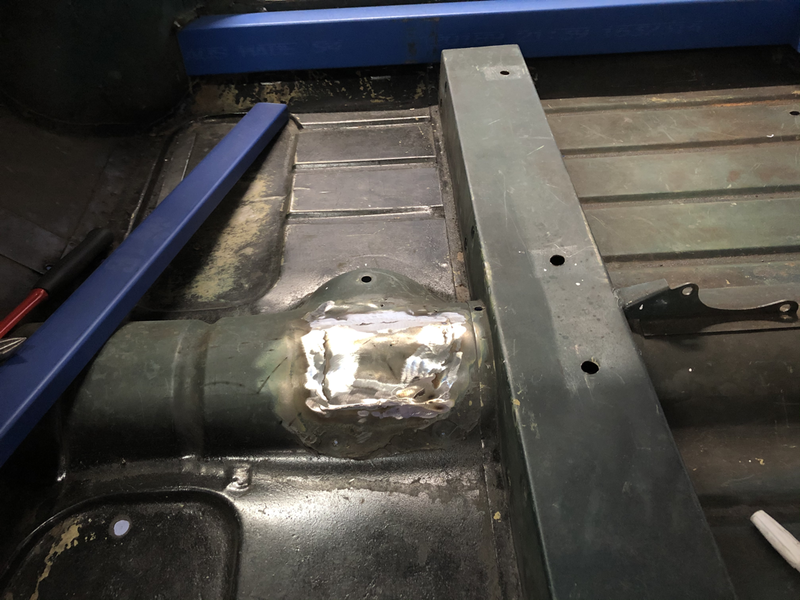

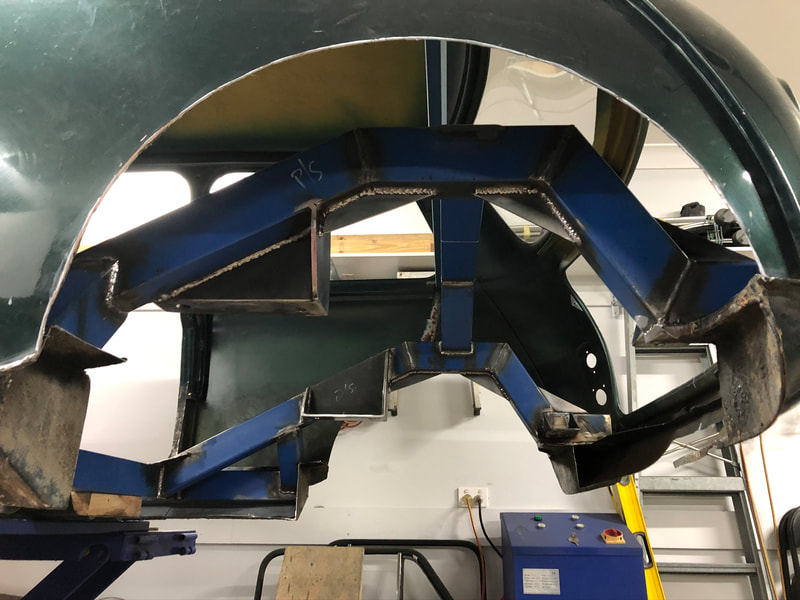

A fair bit of work has been done on the engine subframe and chassis in the way of strengthening. I’ve added the upper control arm mounts and many gussets to stop and twisting or movement under load. The upper arms had to clear the exhaust and turbo which was a challenge hence the metal plate.

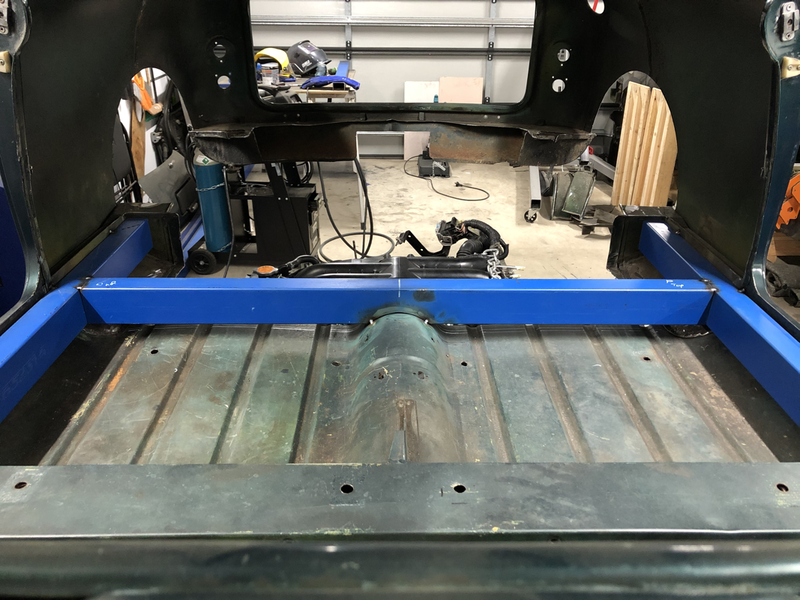

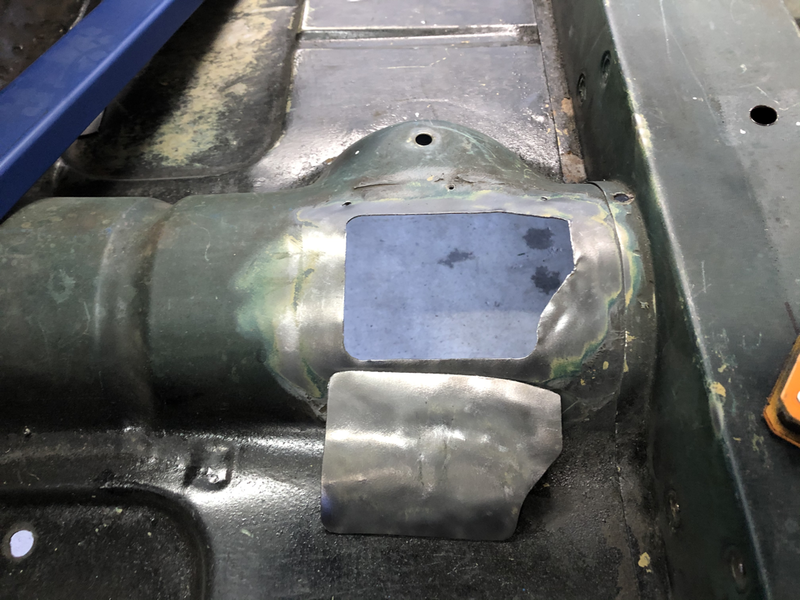

The subframe mounts are made from 6mm thick plate and Definitely won’t be going anywhere. I also filled in the gear linkage hole in the floor as i won't be needing it.

A fair bit of work has been done on the engine subframe and chassis in the way of strengthening. I’ve added the upper control arm mounts and many gussets to stop and twisting or movement under load. The upper arms had to clear the exhaust and turbo which was a challenge hence the metal plate.

The subframe mounts are made from 6mm thick plate and Definitely won’t be going anywhere. I also filled in the gear linkage hole in the floor as i won't be needing it.

6/9/20

Engine in, Engine out. This is going to be a common theme during this build.

Completely welded up the chassis and subframe and added some more gussets. Also added a plate between the floor and cross member of the chassis to cover in the hole and add more strength to the body.

It is now sitting on the rear wheels. No coil overs yet as I need to work out the final weight before they can be ordered and installed. I just put a piece of square tubing in their spot to hold the vehicle up.

Engine in, Engine out. This is going to be a common theme during this build.

Completely welded up the chassis and subframe and added some more gussets. Also added a plate between the floor and cross member of the chassis to cover in the hole and add more strength to the body.

It is now sitting on the rear wheels. No coil overs yet as I need to work out the final weight before they can be ordered and installed. I just put a piece of square tubing in their spot to hold the vehicle up.

A quick time lapse of the rear end assembly.

27/9/20

The front subframe was up next. I am hoping to get the car on all 4 wheels before the lock down ends and life resumes to what is the new normal....

I am using the MX5 upper and lower control arms in the front too. The upper arms will require some additional cutting of the body but will end up ok in the end. It will also maintain the camber and caster adjustment of the MX5 so I can fully align the vehicle once complete. The wheel arches needs more cutting to allow for the wheels to clear when turning. I started with the bottom arms and the frame for that and then the top. The top arms have been positioned similar to the MX5 where they incline towards the front and go out slightly. This is to assist with anti dive when braking. Most production cars have this.

The radiator also was allowed for. I took the WRX mounts and cut them up to suit my application. The WRX radiator and fans fit in nicely to.

Apart from the subframe and body i am trying to keep the components of this project standard so if i want to replace them or upgrade them with after market ones then I have options online and at a retail level. The fuel tank will need to be custom made to fit behind the radiator and inside the subframe. I will need to consider some insulation around the tank too given the heat from the radiator.

The front subframe was up next. I am hoping to get the car on all 4 wheels before the lock down ends and life resumes to what is the new normal....

I am using the MX5 upper and lower control arms in the front too. The upper arms will require some additional cutting of the body but will end up ok in the end. It will also maintain the camber and caster adjustment of the MX5 so I can fully align the vehicle once complete. The wheel arches needs more cutting to allow for the wheels to clear when turning. I started with the bottom arms and the frame for that and then the top. The top arms have been positioned similar to the MX5 where they incline towards the front and go out slightly. This is to assist with anti dive when braking. Most production cars have this.

The radiator also was allowed for. I took the WRX mounts and cut them up to suit my application. The WRX radiator and fans fit in nicely to.

Apart from the subframe and body i am trying to keep the components of this project standard so if i want to replace them or upgrade them with after market ones then I have options online and at a retail level. The fuel tank will need to be custom made to fit behind the radiator and inside the subframe. I will need to consider some insulation around the tank too given the heat from the radiator.