Cleaning & restoring (cont)

The brake booster & master cylinder come up a treat. Also cleaned up a few more items like the brake & clutch pedal cluster, Accelerator pedal, inner CV joint, Gear linkage & steering rack, I changed the standard gear lever with a quick shift lever which will make it more fun to drive hopefully.

Started stripping the wood grain dash on the weekend. It had cracks in the clear coat and was looking pretty worn. I stripped all the components off it and started removing the clear coat by heating it up and scraping it off. Once the clear is off I will sand it, stain it & 2pk clear it again.

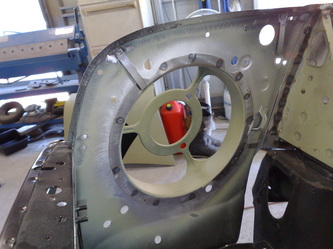

Yesterday it was the 10th November 2010 and I went to see how the repairs on the body were going. Unfortunately not as much was done as I was hoping. The LH front floor pan had been replaced along with the reinforcing plate for the engine subframe. The fabricator was in the middle of replacing the bottom of both doors so the new skins can be fitted. Once the skins are fitted the front can be aligned using the doors. He is going to do the RH side on Friday so hopefully by the end of the weekend the front floors will be finished.

I asked if it will still be finished by the 28th November (2 & 1/2 weeks away) and the answer was yes. Fingers crossed.

I am thinking of fitting an electric glass panel sunroof so I was also going over there to see if it would fit. One of the photos below has a rough template of the glass panel on the roof but as you can see it is too wide. I love my sunroofs but I think this car just has to be left alone to keep it looking its best.

I asked if it will still be finished by the 28th November (2 & 1/2 weeks away) and the answer was yes. Fingers crossed.

I am thinking of fitting an electric glass panel sunroof so I was also going over there to see if it would fit. One of the photos below has a rough template of the glass panel on the roof but as you can see it is too wide. I love my sunroofs but I think this car just has to be left alone to keep it looking its best.

Last week I sanded back the wood grain dash ready for a coat of 2K clear on the weekend. Unfortunately it didn't turn out too good. The clear had little water bubbles in it which then blistered when it dried out. Have to now sand the clear back and go again. This time I’ll make sure the compressor is drained before painting.

After clearing the dash I decided to make a couple of brackets to weld to the bonnet hinges for gas struts. Unfortunately, my car has the original hinges so I used the hinges on the half mini. This worked out quite good as I had to make them fit around the wiper motor, hoses & valves. Turned out quite good I think. I then took them over to my Mini and fitted them up.

Wednesday 24th November and the scuttle panel has been welded in place & the doors put on ready to line the front up.

Unfortunately the engine sub frame that came in the Half cut Mini was bent out of shape. Looked like it had taken a hit and someone heated it up and straighten it. Obviously not a good job as the front panel still wouldn’t line up so I had to go and get another second hand one which was much better.

Still got the Bonnet to repair, the boot floor and weld up a few small holes around the body.

Only a few days to go. Fingers crossed it is finished by Sunday night so I can get make a few mods to the body before sending it to the bead blasters.

Unfortunately the engine sub frame that came in the Half cut Mini was bent out of shape. Looked like it had taken a hit and someone heated it up and straighten it. Obviously not a good job as the front panel still wouldn’t line up so I had to go and get another second hand one which was much better.

Still got the Bonnet to repair, the boot floor and weld up a few small holes around the body.

Only a few days to go. Fingers crossed it is finished by Sunday night so I can get make a few mods to the body before sending it to the bead blasters.

It is now the 29th November and I still don’t have my car back. The fabricator has been delayed and apparently won’t finish it till maybe Thursday. I have it booked in to get bead & sand blasted on Saturday so he has no choice but to ensure it is finished by Friday. We’ll see what happens.

In the mean time, I have finished the wood grain dash by giving it the final coat of clear. I then sanded it back with 2000 grit and then cut & polished it. Came up a treat.

In the mean time, I have finished the wood grain dash by giving it the final coat of clear. I then sanded it back with 2000 grit and then cut & polished it. Came up a treat.

Went over to see how the body was going. Looks like it will be finished a week later than expected. I am picking it up on Saturday 4th December and taking it straight to the bead blasters.